Over the past three years, more than half of the world’s robots were sold in China. While not historically seen as a technological leader in robotics, China is increasingly setting global trends in this industry. Georg Stieler shares his impressions from this year’s CIIF in Shanghai.

Packed, despite a slowdown in sales

Even as China is facing its worst economic sentiment in 20 years, CIIF was vibrant and full of energy. While we estimate a 20% drop in industrial robot sales in the first half of the year—mainly due to a cooling investment boom in electric vehicles, batteries, and photovoltaics—there are bright spots in the market: 3C is gaining in importance again, and cobots are on a growth path, driven by applications in electric vehicle production and inspection.

Key exhibition themes

The leading robotics manufacturers focused on the following key themes at the exhibition:

FANUC presented applications for battery production, cutting, painting, palletizing, and semiconductor manufacturing, as well as dynamic uses of cobots. However, as the market suggests, FANUC is facing challenges due to its high price levels compared to local competitors in the latter segment.

ESTUN showcased its wide product range and industry-specific solutions, particularly in the battery, solar, and automotive sectors. Cobots were more prominently featured than in 2023.

KUKA and ABB demonstrated applications that highlight the technical strengths of their robots and differentiate them from local competitors. As a premiere, ABB introduced the Ultra Accuracy feature for the GoFa Cobot for ultra precise cobot applications in the electronics, automotive, aerospace, and metalworking industries.

Additionally, the following topics were highlighted at the exhibition:

Cobots in EV production: Assembly and inspection applications in batteries and electric vehicles have become a major growth driver for cobot sales. UR, Aubo, Jaka, and Flexiv presented their respective solutions for this field prominently.

Cobots with 30-40 kg payload: Complete palletizing solutions, including cameras, grippers, and software, start at €12,000 — significantly less than comparable solutions in Europe or the US. Pictured is a solution from FANUC at the upper end of the price range.

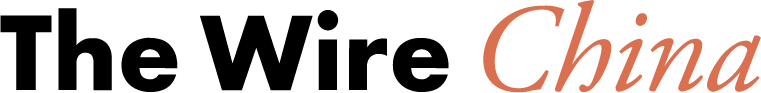

Intelligent welding solutions: 3D cameras and automated path planning were featured by all major cobot manufacturers. QJAR, a domestic supplier, presented a large-scale welding solution for steel structures and claimed to have sold 2,000 robots in a single batch, doubling its sales.

Heavy load robots: Accordingly, FANUC, ESTUN, ABB, Yaskawa, and others demonstrated their capabilities in this field. Mechmind demonstrated a smart solution that streamlining battery pack assembly using 3D cameras and intelligent path planning. Robots with payloads of 300 kg and higher are expected to see more applications in palletizing within industries such as chemicals, F&B, as well as warehousing and logistics.

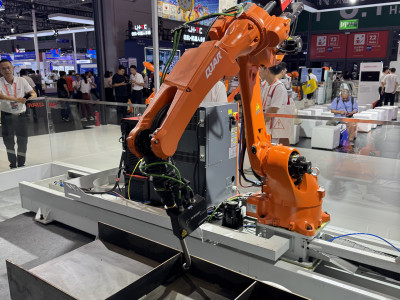

Computer Vision and AI: Mech-Mind showcased its improved solutions for handling shiny and reflective surfaces, as well as its own LLM interface. HIKVISION highlighted 3D-guided welding and advanced inspection tasks and co-exhibited an integrated inspection solution with ESTUN. Agilebots and Micro-Intelligence, a start-up, presented a model in which robots assemble building blocks autonomously.

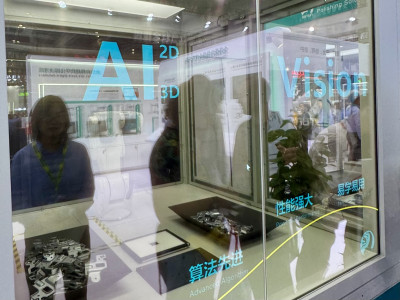

Advanced tactile intelligence: Flexiv and JAKA showed advanced wire harnessing applications, relying on force sensors and dynamic force control.

Inovance’s Ambitions: Inovance, known as the “little Huawei,” presented their industrial robots in a body-in-white setting. After taking market share from established Japanese players in the SCARA segment, this highlights their ambition in multi-axis robotics. Robots currently contribute less than 5 percent to the company’s revenue, but given Inovance's strong position in industrial automation, this could change quickly. Their real-time synchronous industrial wireless module offered a glimpse into their vision for the future.

Ubiquitous Humanoid Robots: Estun, JAKA, and many other companies presented humanoid robots. So far, they serve more as proof of Chinese firms’ capabilities to churn out new hardware quickly. Even the more promising models are still years away from successful commercialization.

Who will still be around in two to three years?

The robotics sector remains hot in China, but many companies at CIIF, despite their large booths, are not yet profitable. The question remains: who will still be around in two or three years? Inovance and ESTUN stand out, but the future is less certain for others.

Foreign companies must become more Chinese to be successful

Foreign firms face challenges in this competitive environment. Higher prices are one hurdle; another is the lack of local engineering capacity. Special requests sent to Europe are often delayed or lost.

Universal Robots, for example, just signed a strategic partnership with Gree Intelligent Equipment in Zhuhai to address these issues.

While Western politicians call for decoupling, many European companies are doing the opposite, increasing their sourcing from China for greater flexibility and faster product development.

Automotive suppliers are even adopting “Go East” strategies to reduce investment costs in Europe by sourcing machines and robots from China.

Mixed outlook for the domestic market

While some expect a sales pickup towards the end of the year, others remain pessimistic.

However, even if the Chinese market shrinks by 20% this year, it will still be five times the size of the US market and three times the size of the EU.

Chinese robotics companies push abroad

One thing is certain: With intense competition in the domestic market, attractively priced products, a powerful ecosystem rapidly producing new solutions at unmatched speed and cost, and extensive application knowledge from the world’s leading manufacturing hub, Chinese robotics companies are expanding abroad. Expect to see much more of them in Asia, the EU, and the US. As I finish this summary, Inovance has just announced plans to exhibit their industrial robots at SPS in Nuremberg this coming November.